DMH Fabrication's FD Build

#1

Disclaimer: Most of this work was done in our home garage due to the new garage being built at the time. This thread is just to show off the project, not the facilities.

I wanted to post this thread to show some of the type of work that DMH Fabrication can do. We are a small operation currently, but offer many different services to our customers. Here is a thread detailing most of the build of our 1994 RX7 R2. It started off by purchasing a right hand drive 1994 Efini RX7 R2 with only 50k miles on it that we found on ebay of all places.

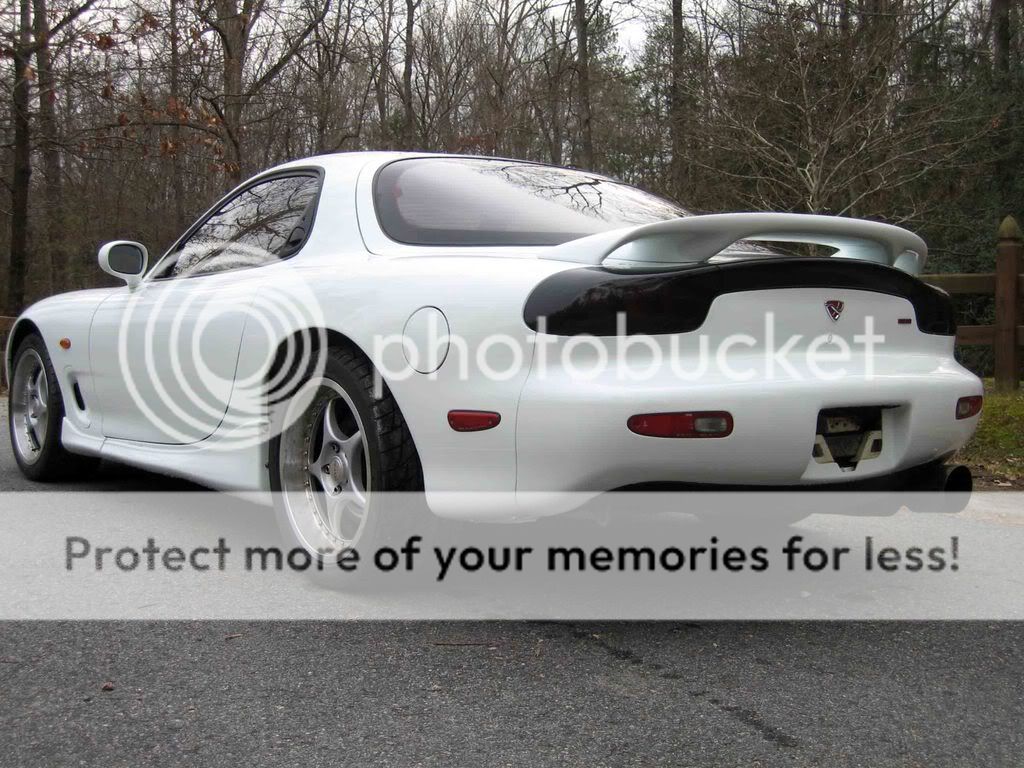

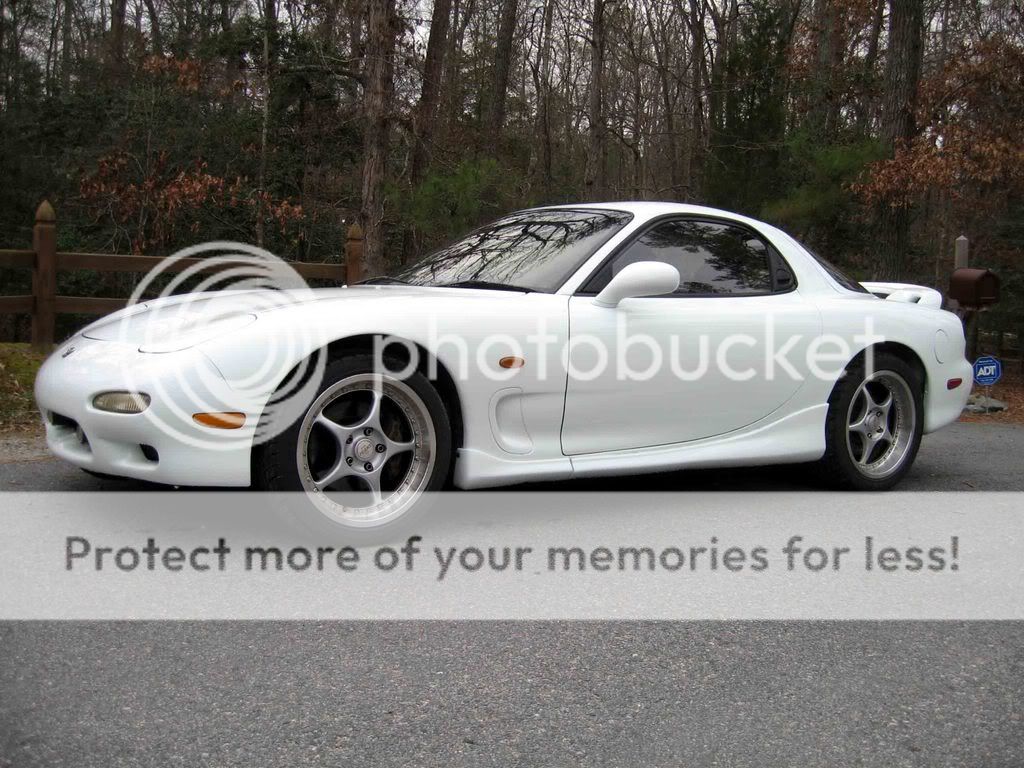

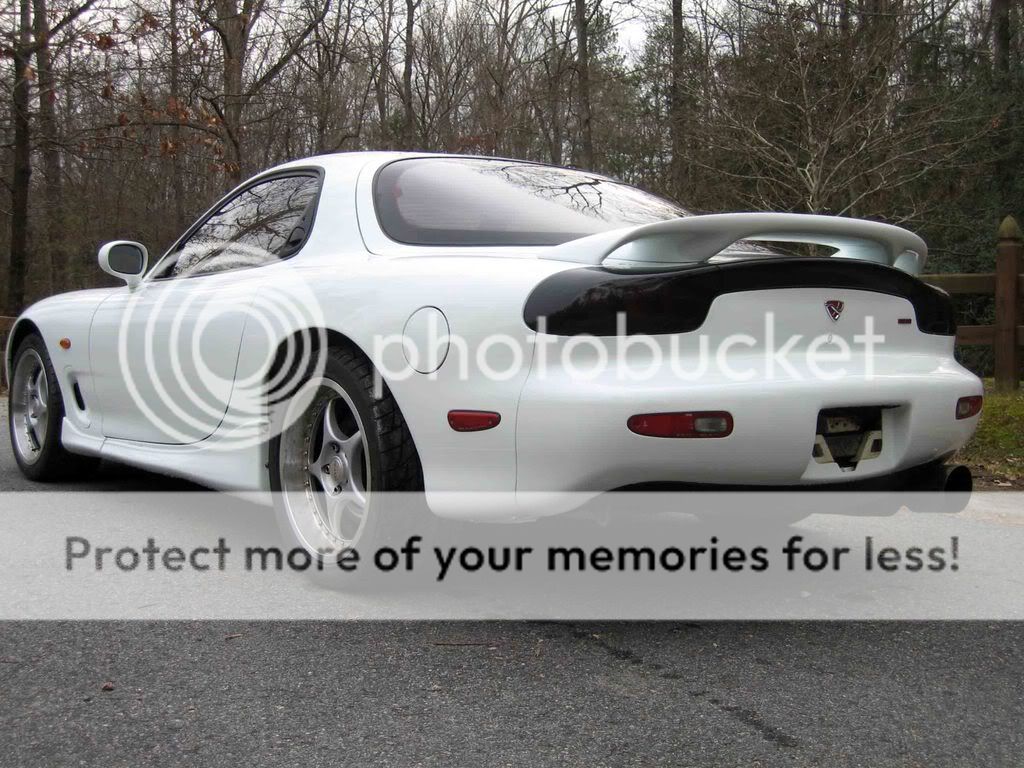

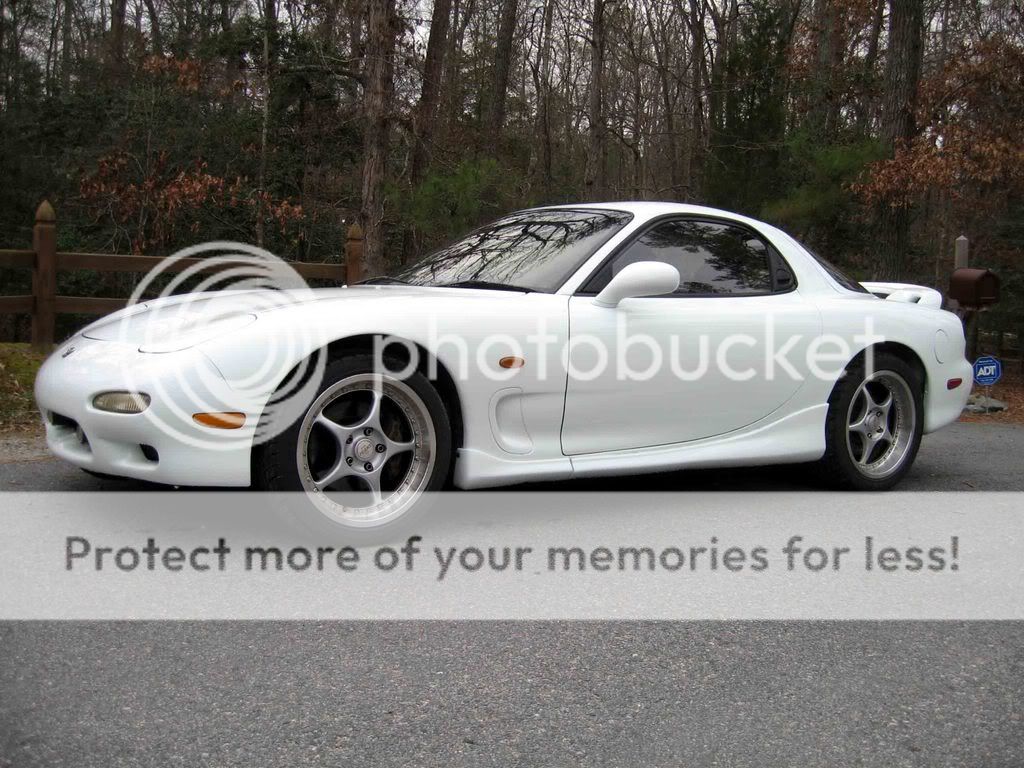

The body was in decent shape, but the front bumper had a large scuff from someone running into something, the front plate holder riveted to the bumper had to go,and there were several dents on the car. The paint was also aged and therefore in need of some bodywork and a new paintjob done by myself. We decided to update the color by switching to Subaru Aspen White. Here are some pictures of how the car turned out after the paint, which was all done by DMH Fab as well:

The next thing on the list to do was lowering the car on the factory Ohlins suspension, and giving the wheels a much needed makeover. We also finished up the DIY ’99 spec taillights while we had the car apart for paint and body work. Don't mind the tag on the car, it was on my last LS6 FD so I temporarily had it transferred to the R2. It's no longer on the car.

About 6 weeks after painting the car, it began to develop a hot start issue and began to use coolant. We pulled apart the motor to find the following:

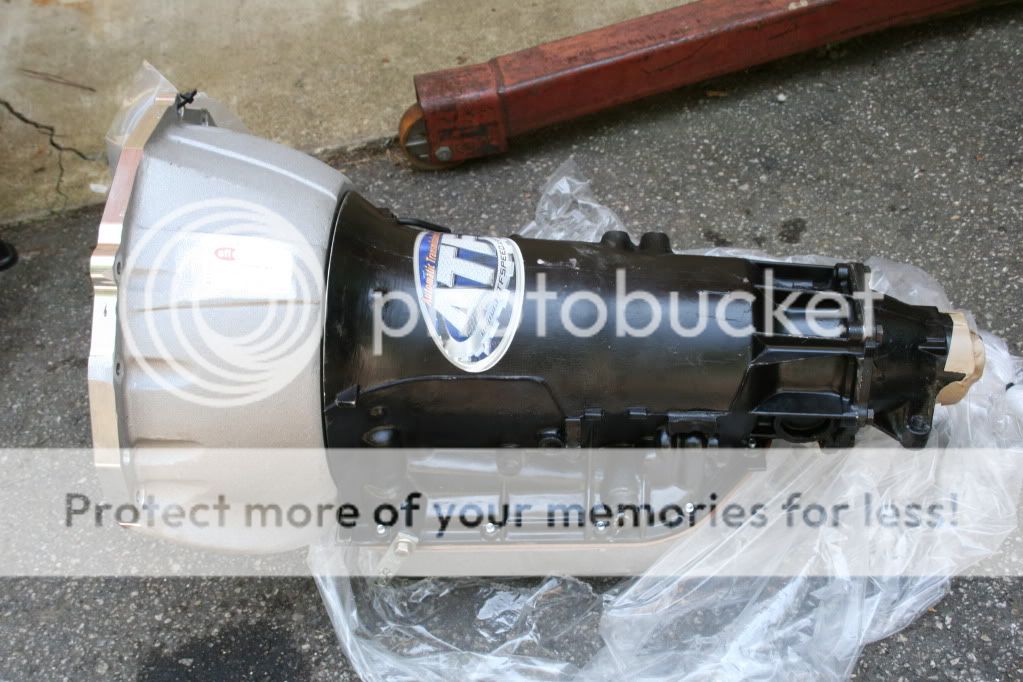

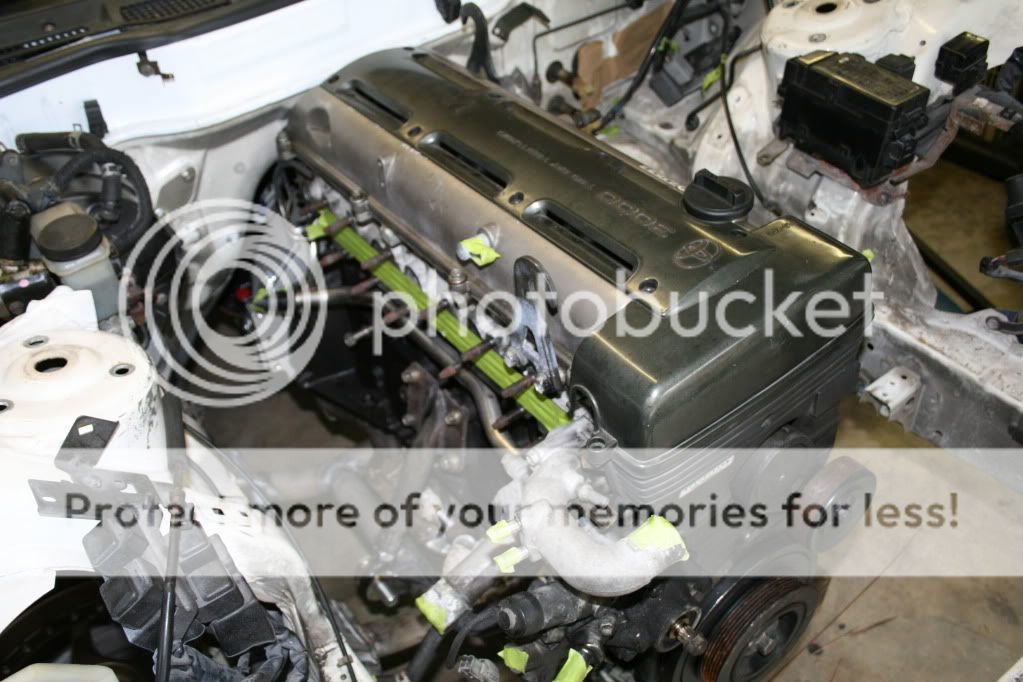

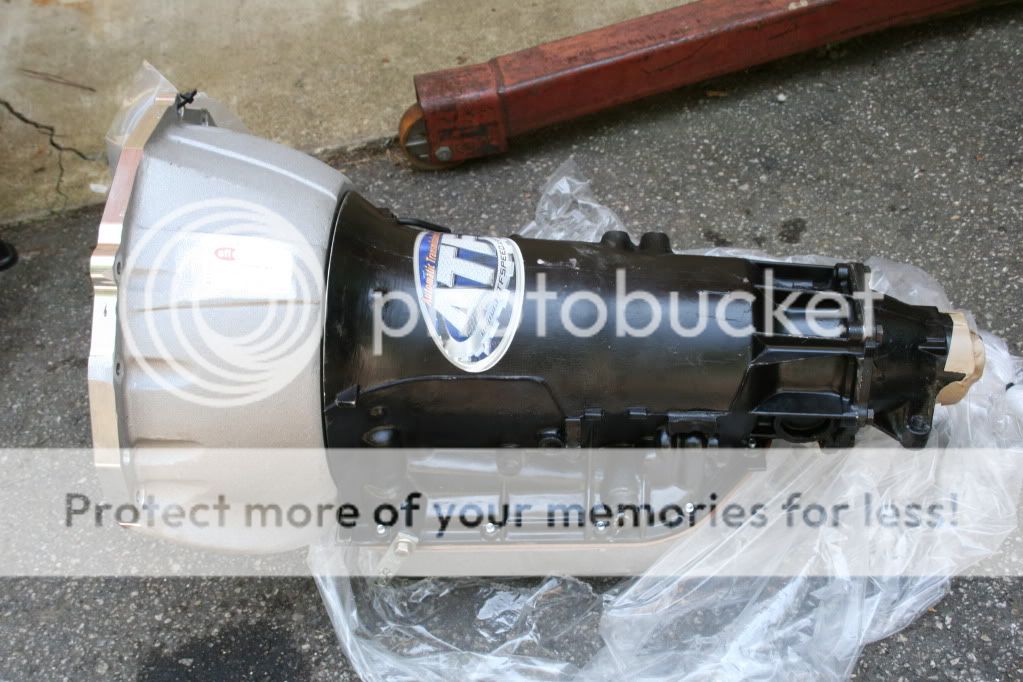

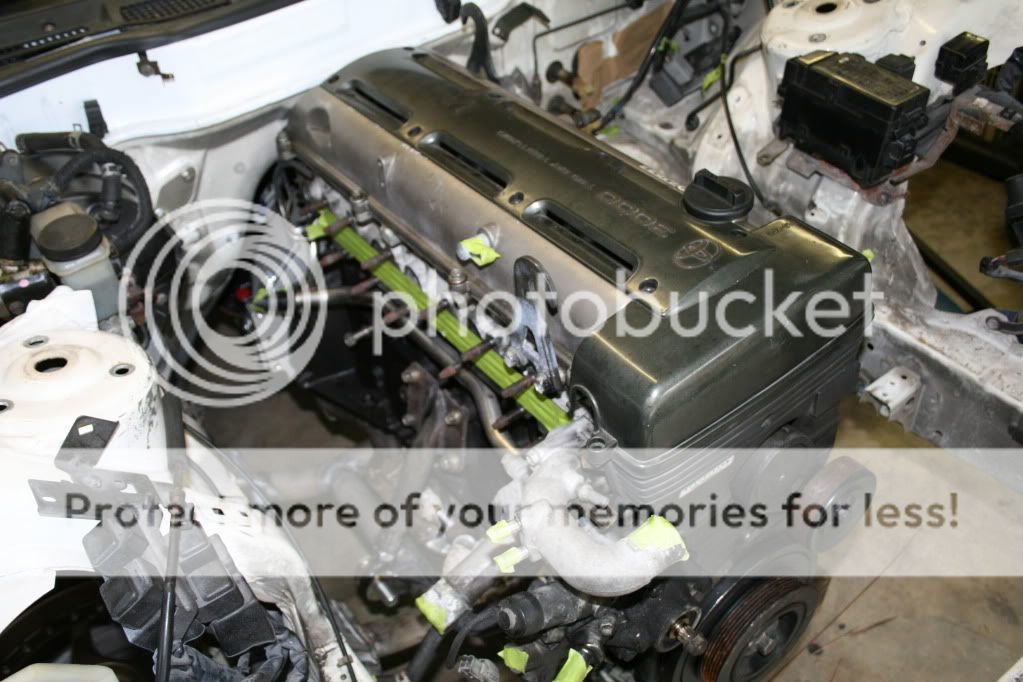

This pudding-like mixture of oil and coolant was literally in every cavity in the motor. It was in the oil pan, in all of the coolant passages, and it was even in every bit of the charge piping, intercooler, inside the engine, and also managed to puke itself backwards through the intake on the air filter as shown above. The coolant seals were completely toast. We parted out the longblock and transmission and began to buy parts and materials for the real build. We already built an LS6 RX7 a few years ago, so we decided to do something just a little different. We did some research and decided to use the infamous 2JZGTE, so we picked up an Aristo 2JZGTE. It is the same engine as the Supra, but with a front sump oil pan, smaller cams, ceramic blade turbos, and a couple other small differences. I considered using the Getrag 6-speed in the car, but realized I wanted a drag car that could see some street duty, not the other way around, so I chose a built TH400 transmission from ATF with a reverse manual valve body built to handle 900+ hp. I made sure to get an SFI approved JW Superbell bellhousing for safety reasons, and it was CNC machined to gain some extra clearance around the engine and transmission tunnel.

In order to mate the GM transmission to the Toyota engine, we used an aluminum adaptor plate and an SFI approved billet aluminum flex plate that bolts to the 2JZ engine and has a GM torque converter bolt pattern.

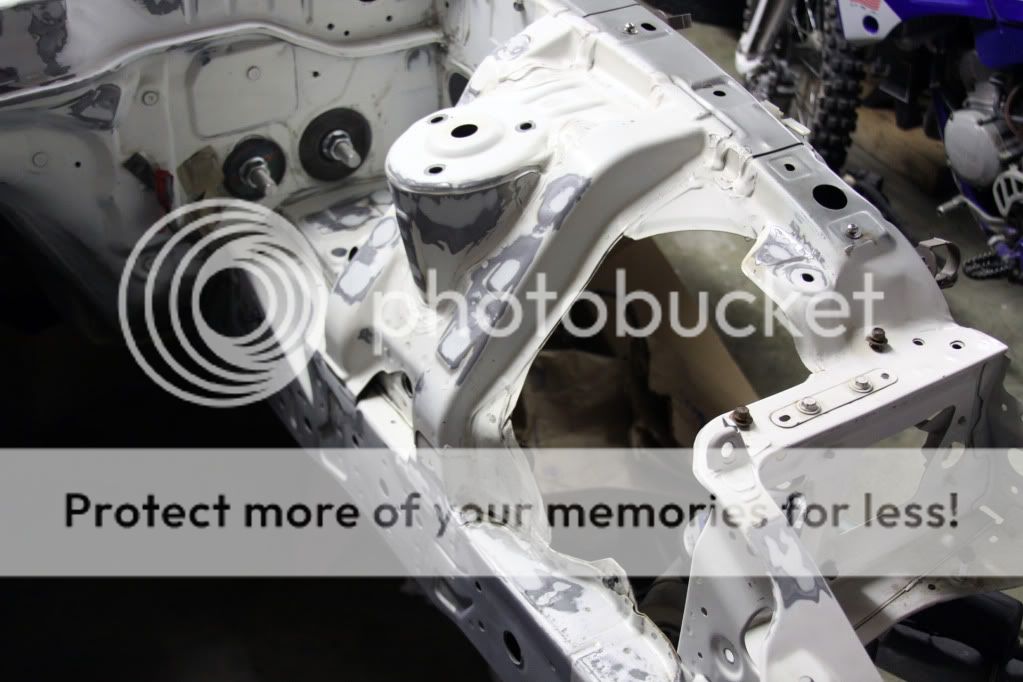

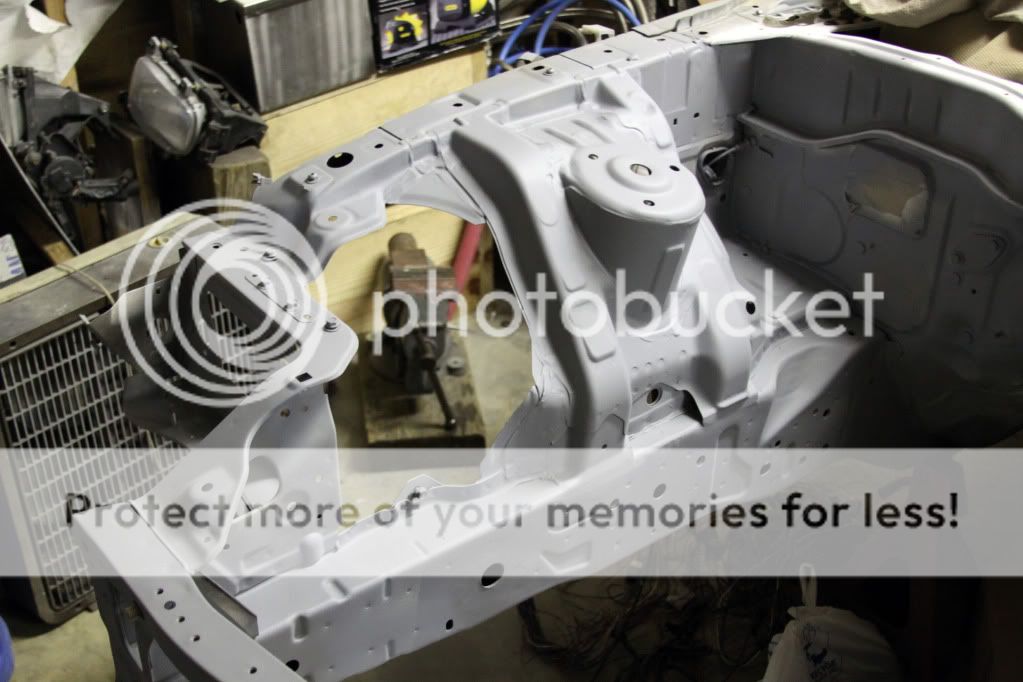

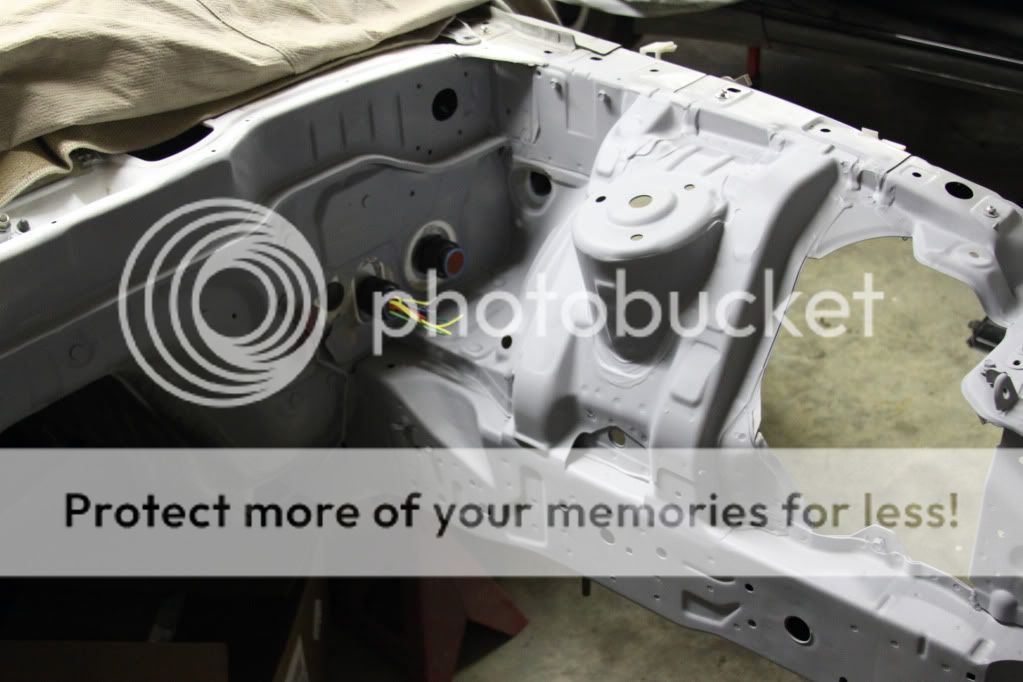

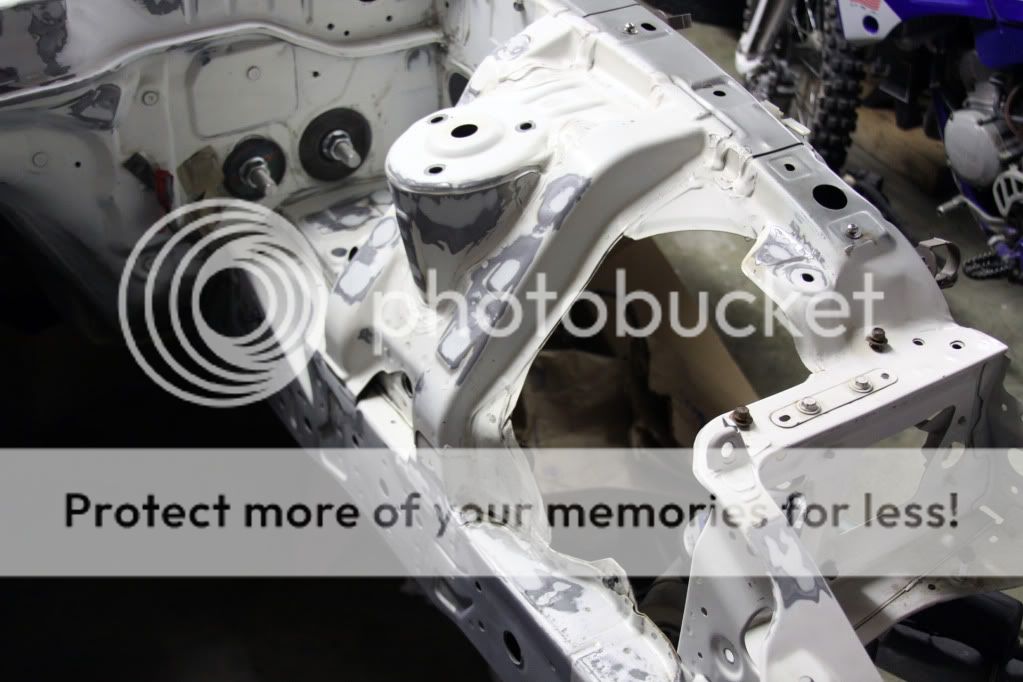

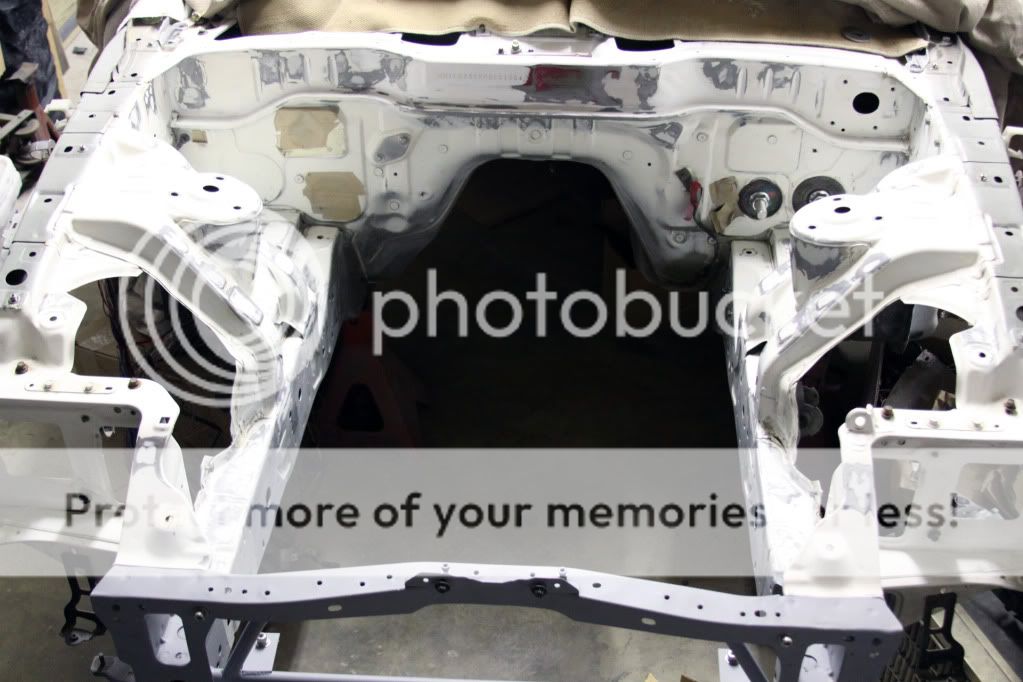

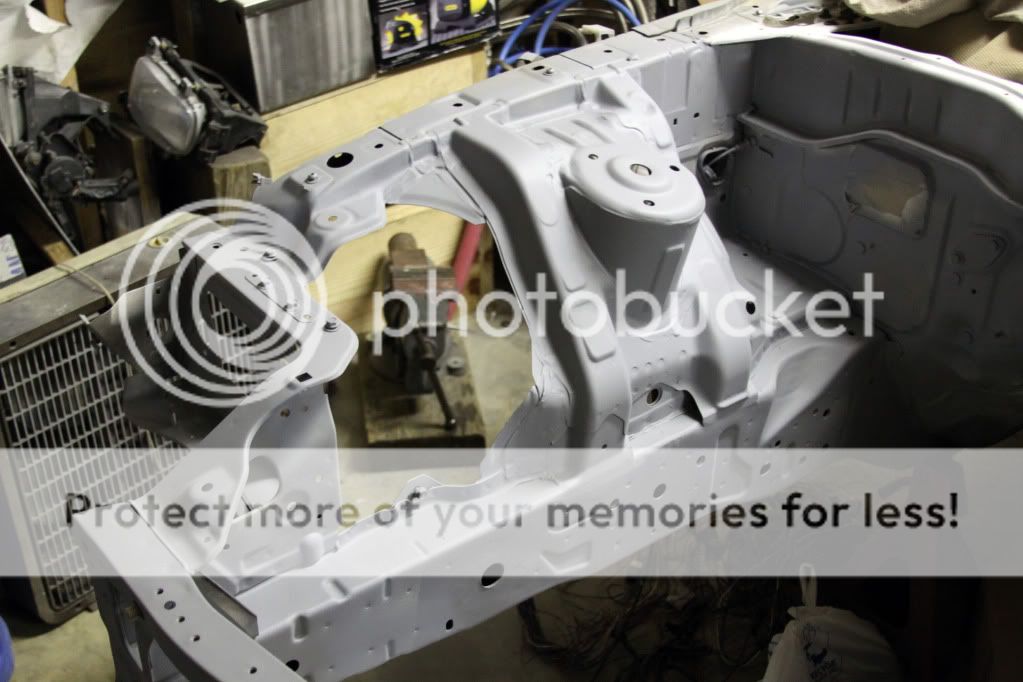

From there, we ordered some chromoly and got to building the custom subframe and transmission mount. We had several goals when building the engine mounts and subframe that included: using the stock hood on the car without adding any scoops or a cowl, minimizing the bumpsteer induced by lowering the steering rack, keeping the engine as far back and as low as I could to keep the CG and F/R balance in check, and utilizing solid mounts for the engine via ¾” rod ends. Here are some pictures from the subrame build:

After finishing up the subframe, we powder coated it with a chrome base and then a candy blue top coat. It came out really nice and sits the engine exactly where we wanted it.

I wanted to post this thread to show some of the type of work that DMH Fabrication can do. We are a small operation currently, but offer many different services to our customers. Here is a thread detailing most of the build of our 1994 RX7 R2. It started off by purchasing a right hand drive 1994 Efini RX7 R2 with only 50k miles on it that we found on ebay of all places.

The body was in decent shape, but the front bumper had a large scuff from someone running into something, the front plate holder riveted to the bumper had to go,and there were several dents on the car. The paint was also aged and therefore in need of some bodywork and a new paintjob done by myself. We decided to update the color by switching to Subaru Aspen White. Here are some pictures of how the car turned out after the paint, which was all done by DMH Fab as well:

The next thing on the list to do was lowering the car on the factory Ohlins suspension, and giving the wheels a much needed makeover. We also finished up the DIY ’99 spec taillights while we had the car apart for paint and body work. Don't mind the tag on the car, it was on my last LS6 FD so I temporarily had it transferred to the R2. It's no longer on the car.

About 6 weeks after painting the car, it began to develop a hot start issue and began to use coolant. We pulled apart the motor to find the following:

This pudding-like mixture of oil and coolant was literally in every cavity in the motor. It was in the oil pan, in all of the coolant passages, and it was even in every bit of the charge piping, intercooler, inside the engine, and also managed to puke itself backwards through the intake on the air filter as shown above. The coolant seals were completely toast. We parted out the longblock and transmission and began to buy parts and materials for the real build. We already built an LS6 RX7 a few years ago, so we decided to do something just a little different. We did some research and decided to use the infamous 2JZGTE, so we picked up an Aristo 2JZGTE. It is the same engine as the Supra, but with a front sump oil pan, smaller cams, ceramic blade turbos, and a couple other small differences. I considered using the Getrag 6-speed in the car, but realized I wanted a drag car that could see some street duty, not the other way around, so I chose a built TH400 transmission from ATF with a reverse manual valve body built to handle 900+ hp. I made sure to get an SFI approved JW Superbell bellhousing for safety reasons, and it was CNC machined to gain some extra clearance around the engine and transmission tunnel.

In order to mate the GM transmission to the Toyota engine, we used an aluminum adaptor plate and an SFI approved billet aluminum flex plate that bolts to the 2JZ engine and has a GM torque converter bolt pattern.

From there, we ordered some chromoly and got to building the custom subframe and transmission mount. We had several goals when building the engine mounts and subframe that included: using the stock hood on the car without adding any scoops or a cowl, minimizing the bumpsteer induced by lowering the steering rack, keeping the engine as far back and as low as I could to keep the CG and F/R balance in check, and utilizing solid mounts for the engine via ¾” rod ends. Here are some pictures from the subrame build:

After finishing up the subframe, we powder coated it with a chrome base and then a candy blue top coat. It came out really nice and sits the engine exactly where we wanted it.

Last edited by GSXRATED; 09-24-2010 at 02:41 PM.

#2

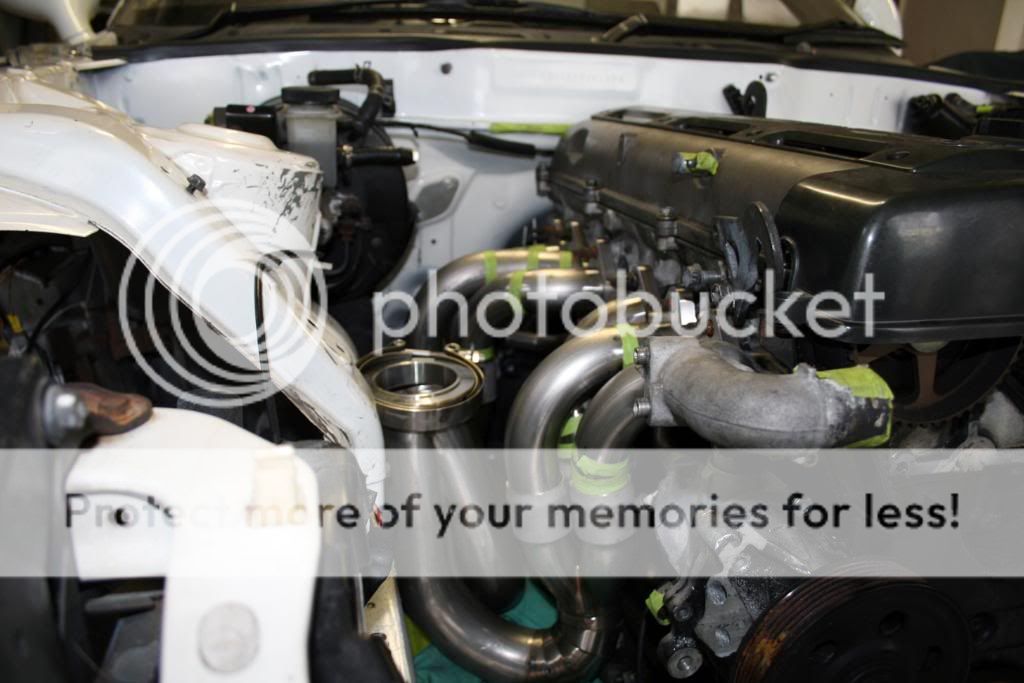

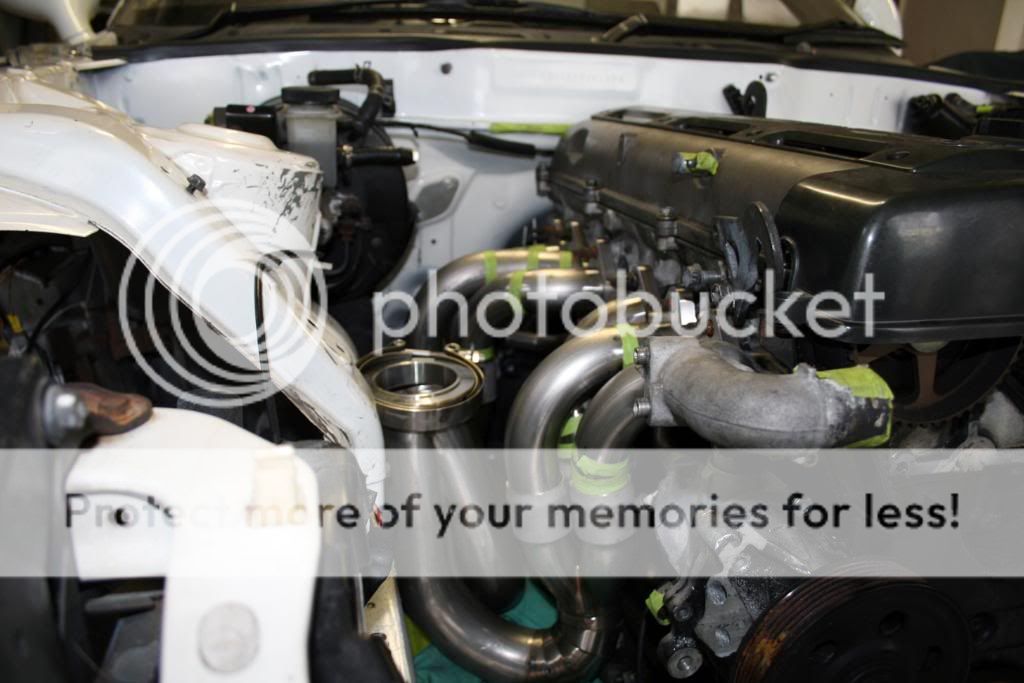

The next step was the exhaust manifold fabrication. Sure, we could have just purchased a Supra manifold and called it a day, but we like building cars, not bolting parts together. We also wanted to use one of the new Tial V-band turbing housings, so a custom manifold was in order. We ordered some 321 stainless steel from Burns Stainless for its resistance to cracking at extreme temperatures, low thermal expansion, and excellent corrosion resistance. The head flange was CNC machined from 304 stainless steel also. We picked out a Precision GT4276 turbocharger and ordered a Tial V-band turbine housing for the build. This is what we received several weeks later:

Here is a ping-pong ball for a size comparison.

After we had the turbo, we got to work on the manifold. We’re using 1.75” primaries, two 3-1 double-slip merge collectors from Burns Stainless, and then two 2.25” secondaries that merge just before the v-band flange.

While we were working on the car, we also cleaned up the bay by removing the ABS and I am working on pulling a lot of unnecessary wiring from the body harness to make the engine bay as open and clean as possible.

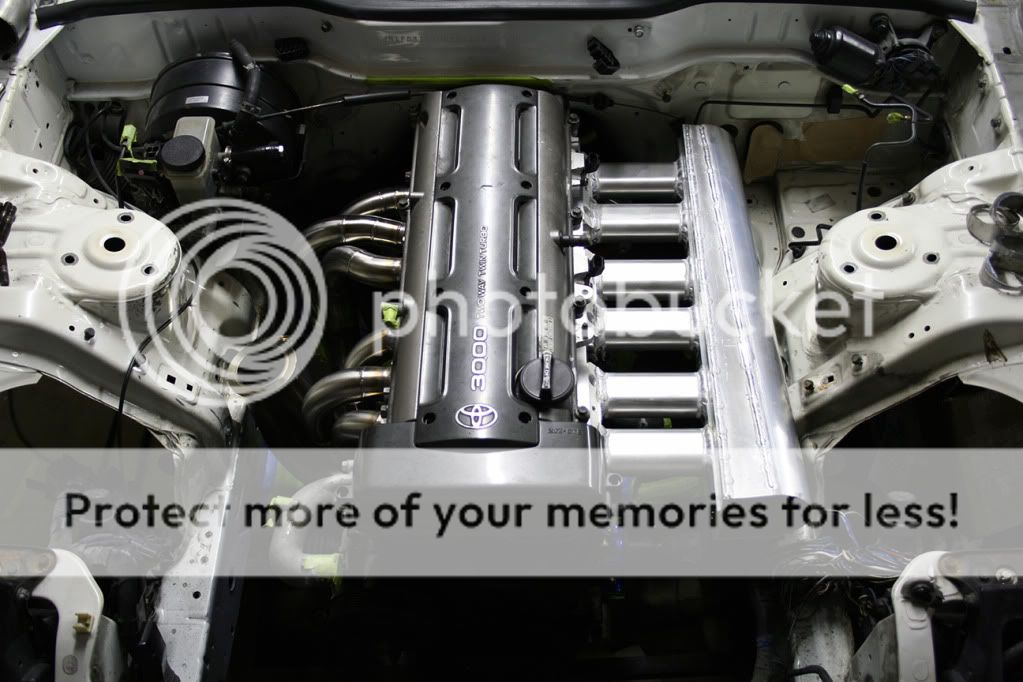

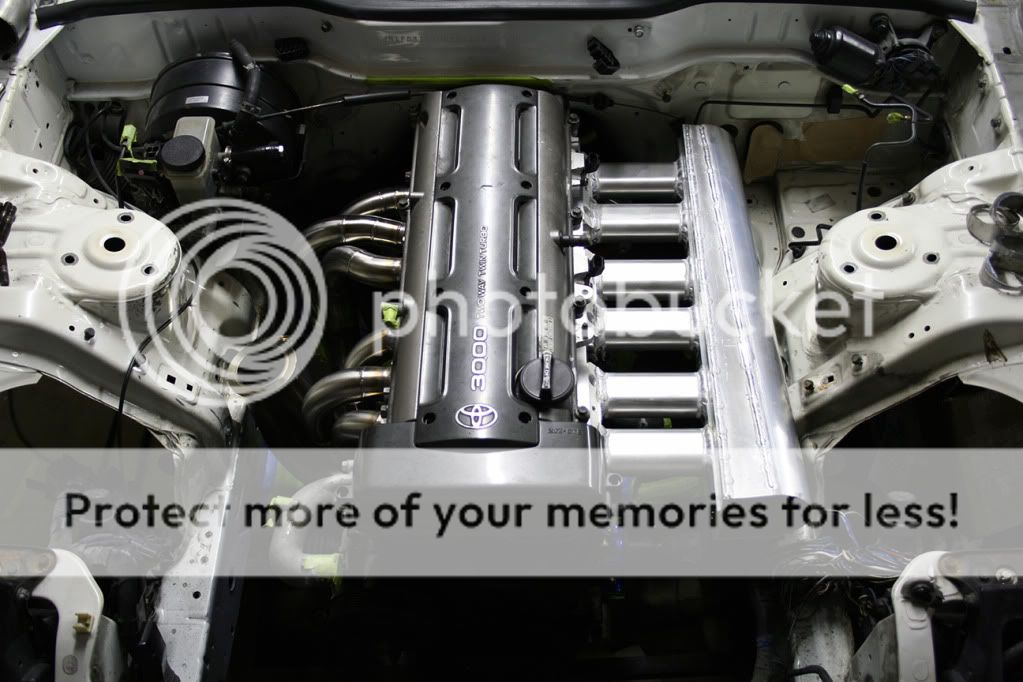

The manifold took about 23 hours of work to get it finished. The intake manifold was designed using Unigraphics NX6 CAD modeling and CFDesign 10.0 fluid dynamics in order to create an even distribution of airflow into each cylinder. The manifold has the head flange, runners, and plenum base plate welded, ground, and smoothed into each other also. The custom CNC throttle body flange was also made by DMH Fab.

Here is a ping-pong ball for a size comparison.

After we had the turbo, we got to work on the manifold. We’re using 1.75” primaries, two 3-1 double-slip merge collectors from Burns Stainless, and then two 2.25” secondaries that merge just before the v-band flange.

While we were working on the car, we also cleaned up the bay by removing the ABS and I am working on pulling a lot of unnecessary wiring from the body harness to make the engine bay as open and clean as possible.

The manifold took about 23 hours of work to get it finished. The intake manifold was designed using Unigraphics NX6 CAD modeling and CFDesign 10.0 fluid dynamics in order to create an even distribution of airflow into each cylinder. The manifold has the head flange, runners, and plenum base plate welded, ground, and smoothed into each other also. The custom CNC throttle body flange was also made by DMH Fab.

#4

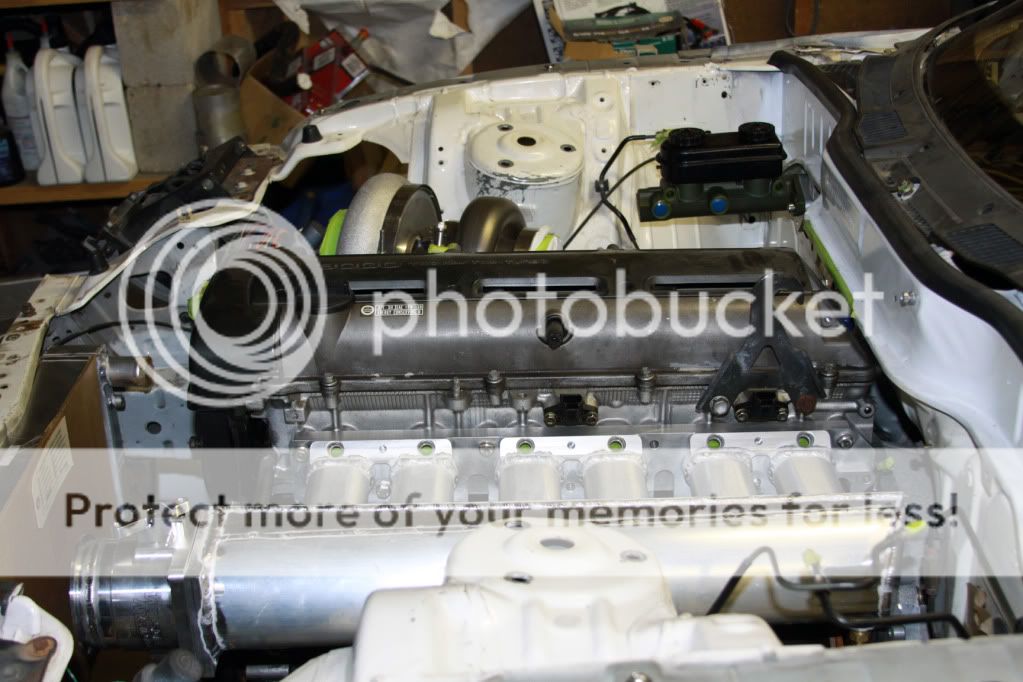

We finished fabbing the intercooler end tanks, welded the v-band flanges to the back-door end tanks, welded the end tanks to the intercooler core, removed a bar in the way of the intercooler's location ( a chromoly support will be replacing this behind the intercooler), and made mounts for the intercooler and also welded those on. The front bumper cover has been trimmed to accommodate the massive intercooler. We also went ahead and welded a v-band flange onto the Wilson 90mm throttle body that will allow us to eliminate a coupler location to ensure no couplers blow off on the car under high boost. We also removed the factory brake master cylinder and replaced it with a Strange manual brake master that is shown mocked up in its location in the pictures. That part will save us some weight, gain extra clearance for the downpipe, clean up the engine bay even more, and get rid of one more vacuum line on the car. We have also removed the factory gas tank and have already modeled a 10 gallon aluminum tank to take its place in the car. We did some more wiring removal and clean up as well to get rid of 6 unnecessary relays and a bunch of associated wiring.

Notched part of my frame rail for clearance and fabbed up both of my intercooler pipes:

Now that's what I call short route intercooler tubing

The v-band flanges were machined by DMH Fab and we added an o-ring groove in order to provide a nice seal. We have viton o-rings for this. We welded in the chromoly cross bar and radiator cross member support. We also fabricated my radiator mounts off of the new cross bar. My fuel cell will be built this week since I have now finalized my dimensions, and we will finish up my delrin bushings for the front suspension we’re making.

The v-band flanges were machined by DMH Fab and we added an o-ring groove in order to provide a nice seal. We have viton o-rings for this. We welded in the chromoly cross bar and radiator cross member support. We also fabricated my radiator mounts off of the new cross bar. My fuel cell will be built this week since I have now finalized my dimensions, and we will finish up my delrin bushings for the front suspension we’re making.

So, 6 hours of wiring later we have removed a ton of unnecessary wiring, relays, connectors, and relay boxes. The new front half of the body harness is probably 1/4 to 1/3 as large as the original. On the passenger side of my car there were originally about 30-40 wires that passed through the firewall. Now, there are 5. I have a picture of the box of wiring/relays etc. that I pulled out of the car below. It's actually a lot more than it looks like since we wound up the removed wiring and packed it into the box. The body harness of the car is now pretty much finished. I relocated one necessary relay inside the firewall, and have to find a place to tuck away 2 small relays.

We also manufactured delrin front suspension bushings and 4130 steel bushing inserts.

We fabricated the downpipe and wastegate dump tube. We also welded 90% of my fuel tank and installed my brake master cylinder adapter plate.

#6

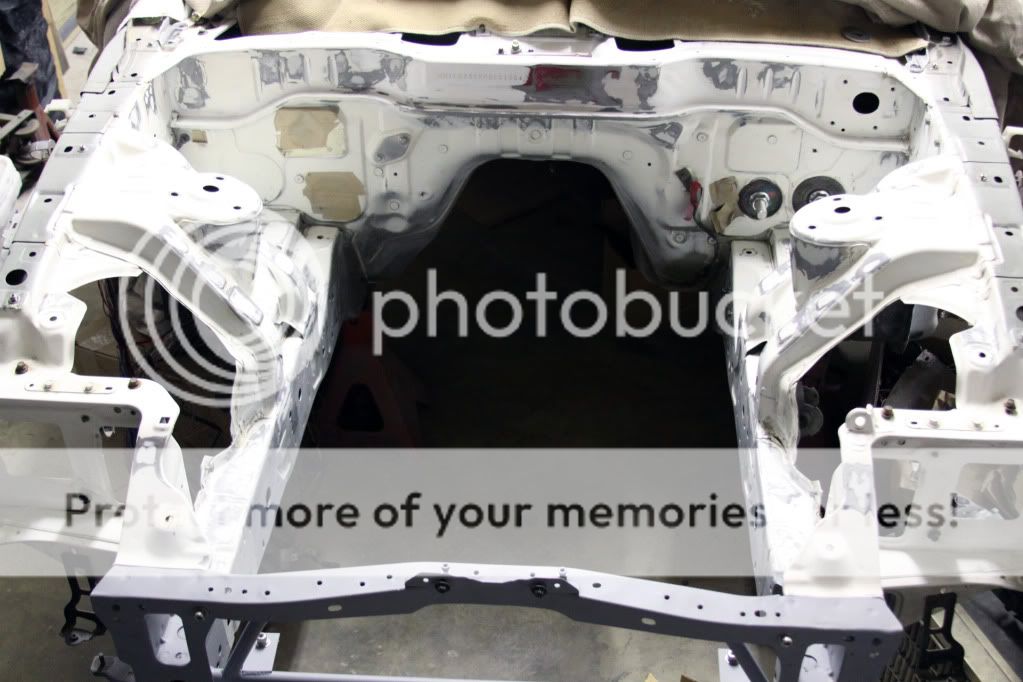

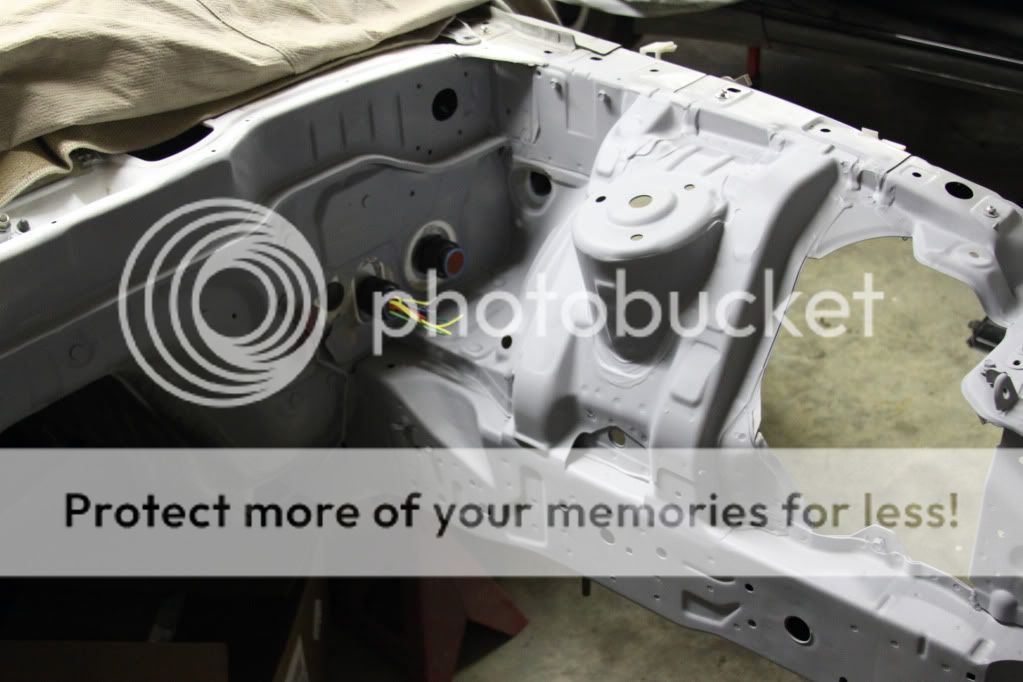

We welded shut about 50 holes that were no longer being used and sprayed some primer until I can get some high build stuff and then paint the bay soon. We also made some block-off plates for the factory a/c firewall pass-through and the factory engine harness grommet with provisions for some deutsch connectors that will be used for the engine harness.

#8

Just for the record, this was the status of the car about 6 months ago. It is pretty much done now, i just need to tie up some loose ends and get some more pictures. Also, I have no problem with rotary cars, and enjoyed this one with the rotary. I have just always liked the 2JZ but didn't like the weight of the Supra.

in for this

in for this